Tying machine AS 2.1

AS 2.1 M

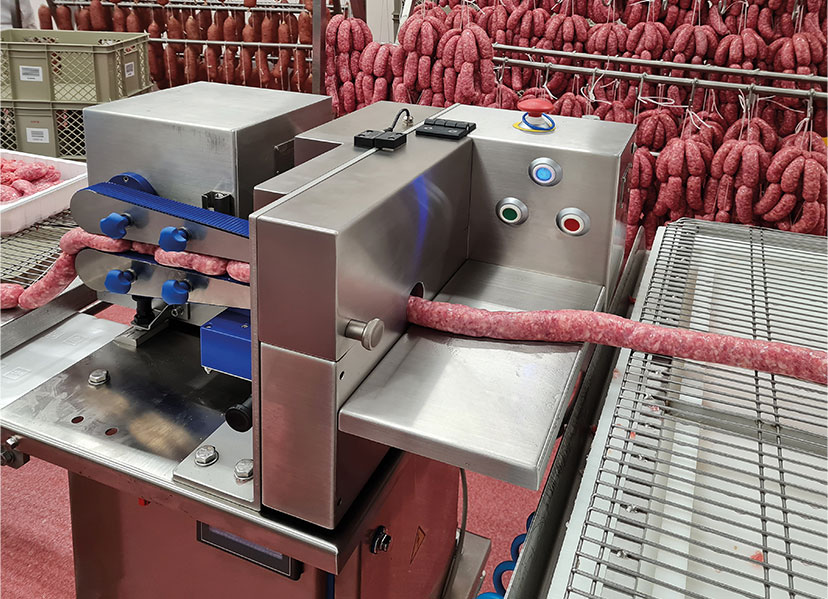

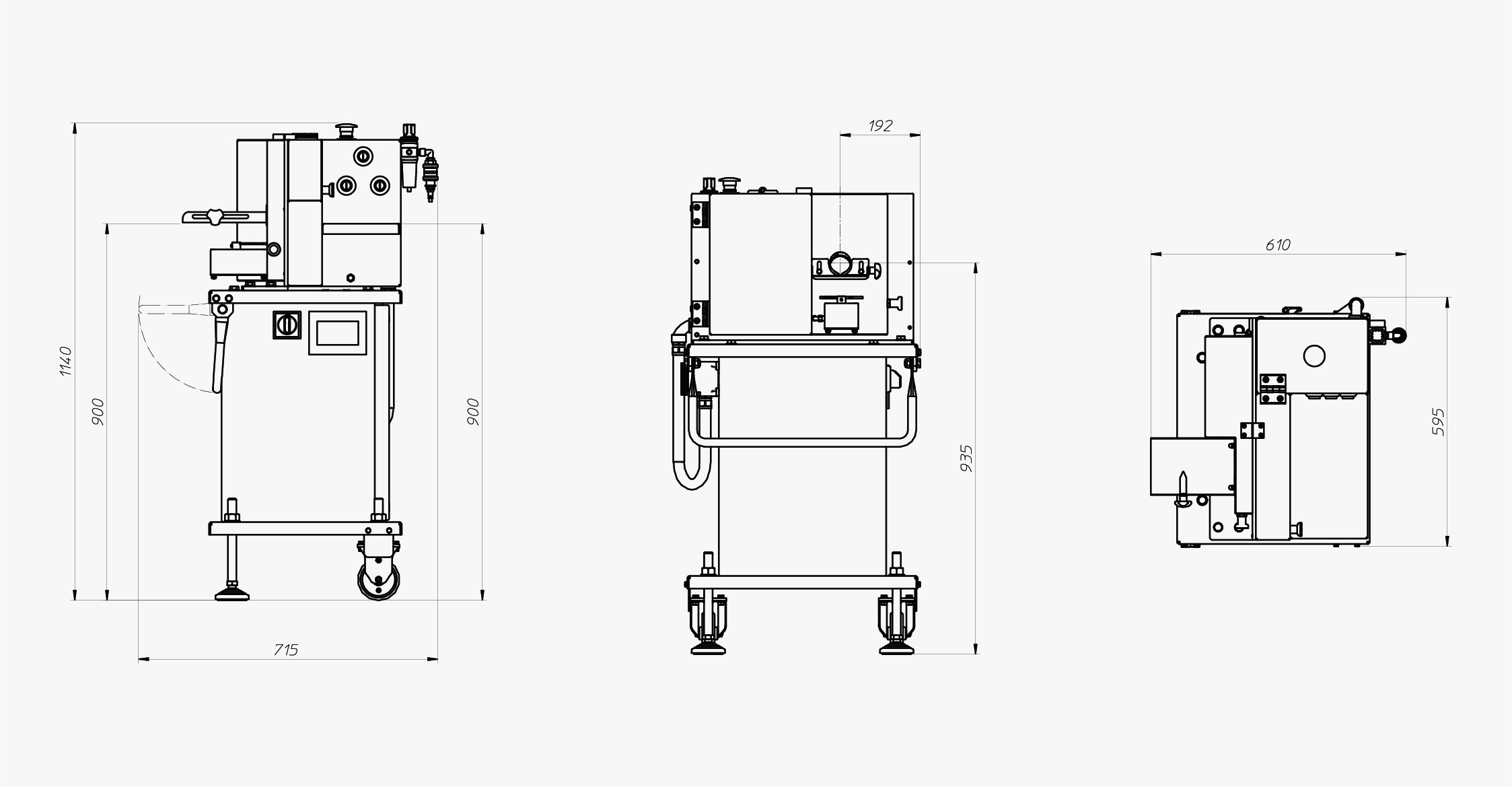

The AS 2.1 M is a semi-automatic tying machine suitable for sausages filled in natural casing with continuous thread, The strength points of this model are its practicity and ease in use, which permits to be used also by operators with low experience. Projected with specific attention to the volume, this model is suitable for small areas: it is equipped with 2 wheels and 2 fixed supports, the movement is made easy thanks to the handle.

AS 2.1 A

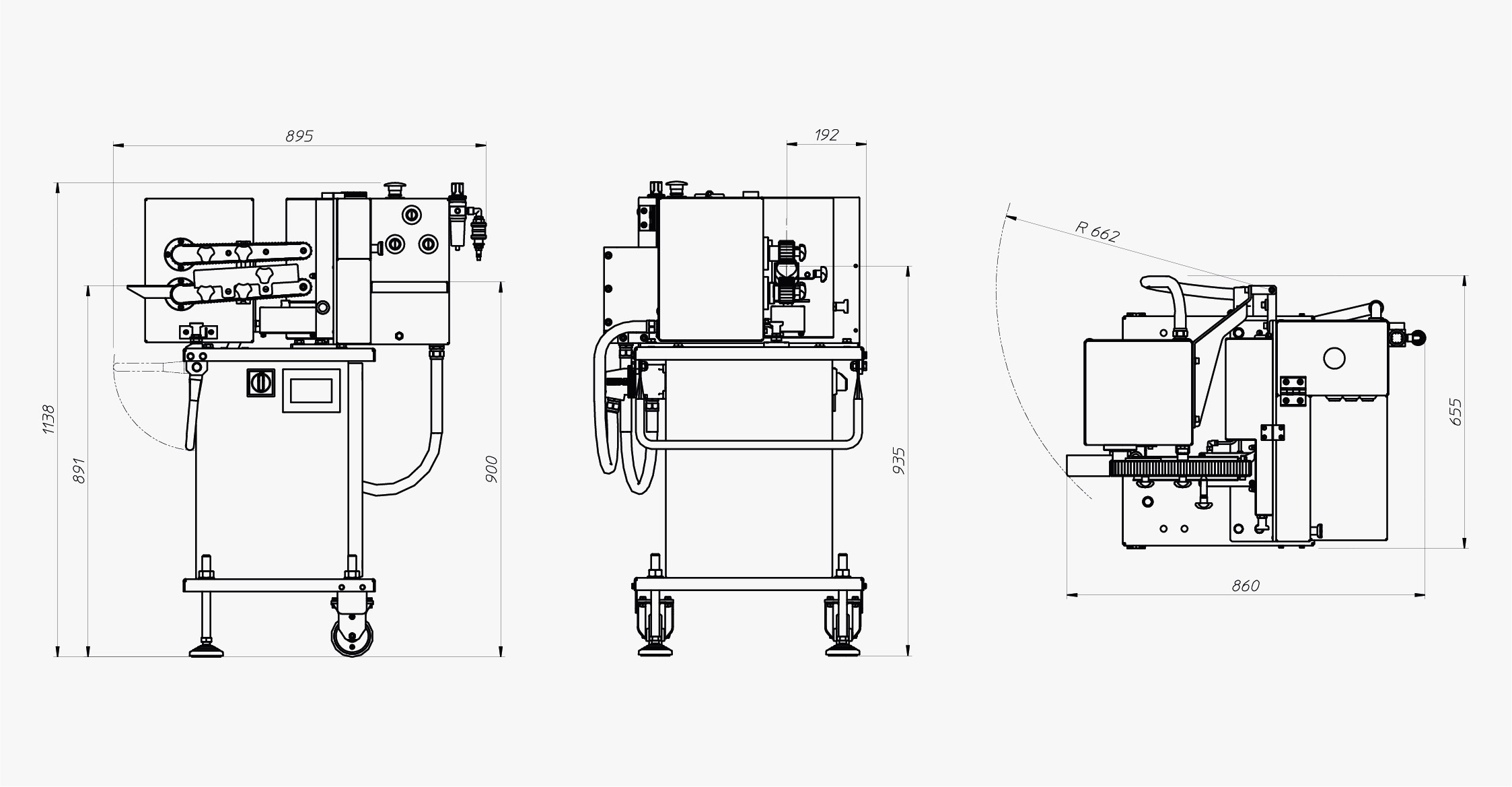

The AS 2.1 A is an automatic tying machine equipped with pulling belts group for sausages. The operator will just need to set the required length and then the machine will automatically pull the sausage to the tying. The two belts are positioned to avoid damages to the product, which will lay on the inferior one; then the superior will be manually adjusted based on caliber. Machine’s cleaning operations and eventual parts replacements are practical and rapid: the machine has been projected in order to disassemble the pulling belts without using keys.

Type of tying: Tying by length

Type of product:

Sausage

Tying machine AS 2.1

Technical features

| Electrical supply: | 230 Volt | |

|---|---|---|

| Pneumatic supply: | 6 bar - consumption: 9lt/min | |

| Tying laps: | from 2 to 4 | |

| Pulling time: | from 0 to 10 seconds with selectors From 0 to 9,99 seconds with touch-screen |

|

| Production speed: | up to 100 cycles/min | |

| Working table height: | from 880 to 940 mm | |

| Dimensions: | 50 x 60 x 120h | |

| Weight: | 103 kg | |

| Type of casing:: | Natural | |

| Products caliber: | 25-48 mm | |

| Electrical supply: | 230 Volt | |

|---|---|---|

| Pneumatic supply: | 6 bar - consumption: 9lt/min | |

| Tying laps: | from 2 to 10 | |

| Product length: | from 10 to 9999 mm | |

| Production speed: | up to 115 cycles/min (it depends on product length) | |

| Working table height: | from 880 to 940 mm | |

| Dimensions: | 62 x 75 x 120h | |

| Weight: | 133 kg | |

| Type of casing:: | Natural | |

| Products caliber: | 25-48 mm | |

LOOP FORMATION SYSTEM

The loop formation system (optional) permits to hang pre-determined groups of sausages. The loop length is 9-10 cm.

Request informations

* required fields

Entrust you to Borgo:

choose the quality and efficiency of our machines for meat’s processing!